The manufacturing industry is undergoing a revolution as electrical and automation solutions become more widely used in industrial processes. This transformation is allowing companies to improve their productivity, reduce costs, and increase quality control. In this blog post, we’ll explore how electrical and automation solutions are revolutionizing manufacturing and the positive impacts they are having on businesses. We’ll look at the different types of solutions available, the advantages they offer, and what the future of industrial automation holds.

Increasing Productivity

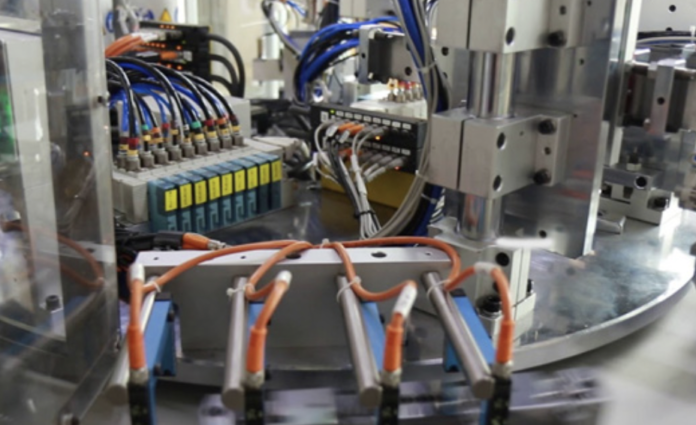

By leveraging the latest in automation technology, industrial processes can be optimized for greater efficiency and improved accuracy. Automated solutions enable businesses to maximize their production output and cut down on labor costs.

Automation technology enables businesses to set up custom production flows to ensure optimal performance. This can help increase overall productivity and reduce manual labor. Automated solutions often require less maintenance and cost than manual alternatives.

Companies can easily configure production schedules to meet changing demands while still ensuring that quality standards are met. This can help businesses stay competitive in the marketplace and quickly meet customer needs.

Optimizing industrial processes with automation technology allows businesses to maximize their output while minimizing labor costs.

Enhancing Quality

One of the most significant impacts of electrical and automation solutions is their ability to enhance product quality. By utilizing automation companies NZ, businesses can ensure that all parts of a process are running as intended, thereby resulting in fewer errors and higher-quality output. Automation also allows for faster production cycles, enabling businesses to produce more products quickly and with fewer resources. This means that businesses can focus on improving the overall quality of their products without having to sacrifice speed or accuracy.

In addition to enhancing quality, electrical and automation solutions can also reduce the risks associated with manual labor. By taking human error out of the equation, businesses can be sure that the products they produce are up to standard and safe for use. Furthermore, automated systems can detect potential problems before they become major issues, allowing companies to save time and money by avoiding costly repairs and replacements.

Automated systems tend to consume less energy than manual labor and can help lower emissions by cutting down on the need for transportation. Moreover, some automated systems are designed to be highly efficient and reuse materials for future projects, helping businesses save money and conserve resources.

Reducing Downtime

Automated systems are designed to respond quickly to changes in input and output parameters, reducing the amount of time needed to restart operations after any unplanned outages. By automating certain processes, the margin of error is greatly reduced and prevents human error from leading to costly interruptions. Automation also makes it easier to manage a wide variety of processes by having one central interface that is easy to use and navigate.

Companies can use automation solutions to monitor their systems in real-time and be alerted when any changes occur. This allows them to identify problems quickly and fix them before they cause a disruption in production. Automation also allows companies to keep better records of their systems and maintain more accurate data, so they can monitor performance levels, identify bottlenecks, and create strategies for improving efficiency.